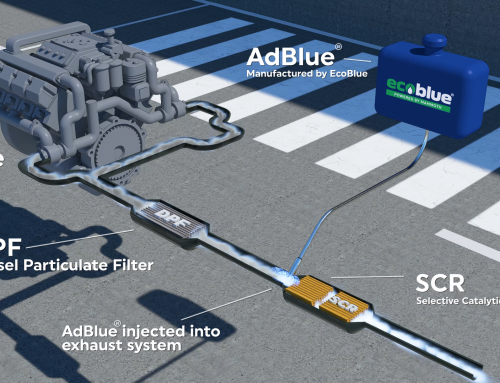

AdBlue® has quickly become an everyday consumable for companies that operate diesel vehicles and equipment. There are many factors to consider when making sure you have the most efficient, safe, and environmentally sound AdBlue® storage option for your business.

1. AdBlue® Usage

Tracking how many litres of AdBlue® you are ordering per month can put into perspective the correct storage option need for your site. For usage under 1000L, drums and Intermediate Bulk Containers (IBC) are a more cost effective and environmentally friendly solution than the smaller 10L bottles.

Businesses running multiple diesel vehicles would likely require a dedicated AdBlue® tank. From 2500L storage capacity, tanks can be a convenient solution to maintain constant AdBlue® supply on-site. Tanks also come with pumping systems to ensure safe and accurate dispensing.

Not sure how much AdBlue® you are using each month? Telemetry systems can be installed on larger tanks to track AdBlue® levels, usage data, and send out a notification when you’re running low.

2. Convenience

Storage space is a major factor in deciding which AdBlue® solution is right for your business. Drums and IBCs are great options for smaller sites, but keep in mind that any empty drums and containers will need to be removed or stored before replacement. However, drums and containers are easily transported and favourable for companies that need their AdBlue® to be mobile.

Remote sites are vulnerable to supply shortages, but a dedicated AdBlue® tank can mean peace of mind. AdBlue® tanks are also a convenient option for businesses with a larger fleet, or that prefer to have less deliveries and less invoicing per year.

3. Control

Larger remote tanks can be fitted with pumping and telemetry systems that require a code or key fob for use. This provides operators with 24/7 access to AdBlue®, while allowing the company to track usage and have control over tank access.

4. Where is it being stored?

AdBlue® is a durable substance and can be stored between 10⁰C – 30⁰C, but with the Australian north often exceeding 40⁰C, heat-guarding options should be considered. Heavy-duty and insulated tanks can protect from sun and hot or cold weather conditions, allowing AdBlue® to be stored anywhere on site. Tanks can also vary in size and shape, to conform to existing infrastructure, or be added to mobile service trucks.

5. Contamination Prevention

Correct storage and handling of AdBlue® is vital for minimising contamination and ensuring a vehicle’s emissions system is working at its optimum. It is important to only use full bottles of AdBlue® at a time and not store partial quantities in unsealed containers. When dealing with bulk amounts, storing AdBlue® in a secure location with high-quality decanting attachments can reduce the chance of contamination and spillage.

6. Environmental and Hazard Concerns

Although AdBlue® is a non-toxic and non-hazardous substance, as with all chemicals, limiting unnecessary human contact and handling, and preventing environmental exposure is best practise. Ensuring dispensing systems are in working order is crucial for limiting human contact. While storing AdBlue® in secure containers and tanks protects surrounding areas from leak and spill hazards.

AdBlue® drastically reduces emissions and is now an essential element of running a diesel fleet. Because AdBlue® is a non-hazardous substance, storage and dispensing systems can be versatile and fit seamlessly within existing infrastructure. Deciding on the right system for your business should be based on convenience and usage needs, making it simpler to provide cleaner air for everyone.